FLEXIBILITY FOR COMPLETE RECYCLABILITY

Published: 23/06/2020

The production scenario in this very particular historical period is characterized by the wider post Covid-19 uncertainty and has seen a sharp slowdown and reduction in the consumption of fossil materials.

Thermoplastic products have however been re-evaluated for their flexibility of use in the disposable sector.

At the same time, there has also been an increase in pollution from plastics in the environment, due to the old and despicable practice of disposing of used material … in the environment!

This period is all about face masks (made out of thin PP fibres particles) and plastic gloves.

A bad habit that continues to do a lot of harm to the planet and to the image of the polymer sector.

Speaking of virtuous recyclability, on the other hand (a topic already covered on our website), we know that to facilitate the recycling process of the product at the end of its life, it is always very important to avoid inserting metal and compound elements in the piece, or on the moulded item, not compatible with the matrix.

In the pharmaceutical, cosmetic and food industries, the focus on single product solutions for rigid packaging is always very strong, as it is the basis for the easy and complete recyclability of the product at the end of its life.

Flexible closures

In the sector of closures, Polyolefins (PP and PE) have allowed over time to optimize many caps for bottles, tubes and dispensers, thanks to their high dimensional stability within certain temperature ranges, as well as excellent flexibility, elongation capacity under load and a good fluidity in the molten state which allowed the development of incorporated hinges.

These applications – the closures – are the best expression of the wide spectrum of features offered by these materials, which are essential to obtain a good final result.

In terms of flexibility / elasticity, dimensional, thermal stability, elongation at break and high fluidity, Biodegradable and compostable materials in industrial compost have for the moment struggled to find a good compromise; but now new products are emerging that can respond consistently to the evolutionary pressure of the sector.

ABM Composite has studied the needs of the rigid packaging market and the relative closures with incorporated hinge. These applications require a particular mix of properties, which are not always easy to find in biodegradable and compostable polymers.

Excellent properties

Based on the research conducted, ABM has developed some products with characteristics compatible with the needs of these applications. Among these the grades: MFA10-C2000 and XB0016 for applications like caps and closures, boxes.

They are characterized by:

- Excellent hinge properties

- Alternative for HDPE, PP

- Compostable in industrial compost

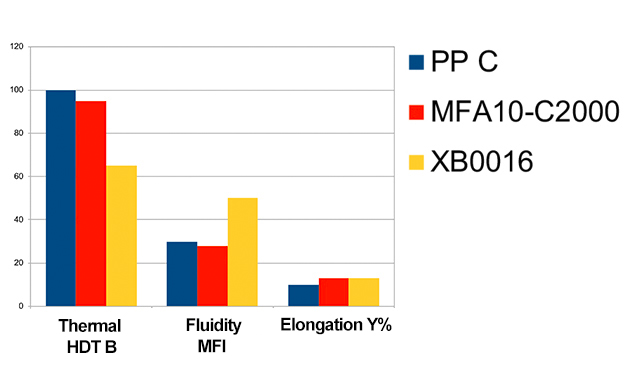

The graph below shows three important parameters for the construction and operation of the hinge closures: thermal resistance under load, elongation at yield and fluidity.

In the graph, the three specific properties are compared with the performance of a standard PP copolymer, a material typically used by the sector.

To find out more about the compostable grades available and their applicability instead of fossil products, send an email to: info@2milasrl.it or call the number: +39.3245969132

Share the article on your favorite social:

Did you find the article interesting?

Are there any topics you'd like to see covered in this blog?

Your comments and requests are important to us: write them in the space below, it's available to you!