2MILA – A SOLUTION PROVIDER FOR POLYCARBONATE CUSTOMERS

Published: 15/05/2020

Today, more than before, the concern about the possible “second life” of fossil polymers is growing and imposes a more holistic approach to the subject by the project leaders.

Today we are a in phase in which the care for the environment must be present in the list of key topics of any project. The EU circular economy approach and directives push all industries in the direction of the prefix “Re”: Re-use, Re-cover, Re-cycle at any level possible. These “re” options should be considered in advance.

This is why designers and engineers must think how to make complex parts easier to disassemble. In the Automotive sector this virtuous approach started many years ago (’90). It was an inter-material competition to reach a mono material solution. At that time Polypropylene was the winner against several traditional polymers.

However, in spite of this important passage, granted by the increase of the technical properties of PP, for many car producers the increase of parts complexity and the low cost of the raw material have reduced the economic leverage to do it. As a result lots of tons of PP were not reused and their end of life was burning or, worse, landfill.

Complexity is often represented by: paints, lacquers, surface chrome or metallization, metal inserts, glues, welding of different materials. Of course these combinations help to make technically outstanding parts but often are a nightmare to re-cycle.

These difficulties also apply to materials with high added value, such as Polycarbonate.

This material brings exceptional properties and characteristics, which can remain available even after its recovery, for new further applications.

The proprieties of Polycarbonate

Polycarbonate is a product that brings a unique combination of technical characteristics, such as:

- →high distortion temperature

- →high impact strength

- →transparency

- →low shrinkage

- →high dimensional stability

- →lower flammability

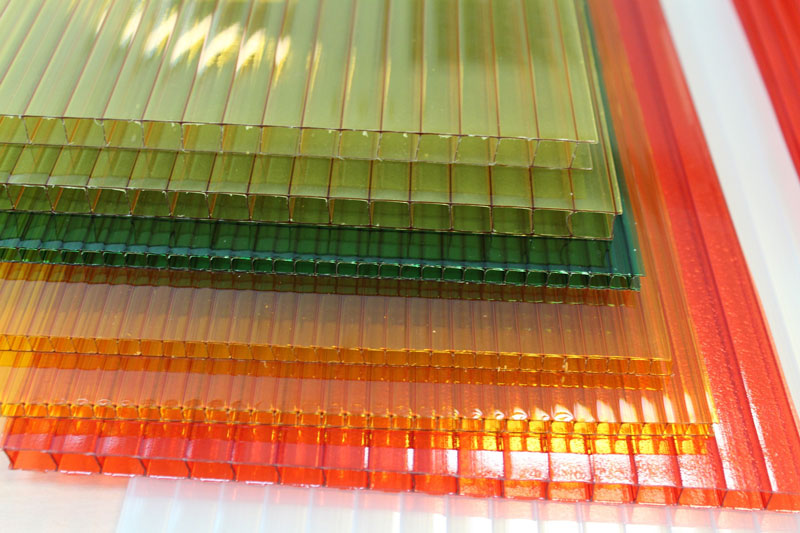

Thanks to these characteristics, Polycarbonate (PC) is the material of choice in the extrusion of compact and structural sheets, profiles and modular engineered panels for building and construction covers and facades, interior partitions of industrial offices and buildings.

Because of its exceptional intrinsic mechanical characteristics, it is possible to design very light structural roofs with important thermal insulation factors, internal compartments and semi-transparent walls which allow to continue to enjoy the natural light coming from the building windows.

2Mila today can offer a specific family of natural Polycarbonates, also with improved resistance to UV rays, with a range of MFI (Melt Flow Index) from 3g/10′ to 6g./10′ able to respond to the extrusion process needs.

In the Extrusion industry segment, the PC-007 UL 1, with 100% linear chain, is now a grade of reference for the production of multi-wall, engineered panels and compact sheets.

The Polycarbonate family of Kazanorgsintez offered by 2Mila also reduces the environmental risks because it is made with the most updated Phosgene-free technology available on the market.

Polycarbonate is one of the products that maintain lots of the original properties and a good economical value in the recycle chain. It is of course worth recovering also for that. However attention should be paid to contaminants during the shredding and the stocking phase. A separation in colors will also help to keep the economical value high.

You can download here the PC-007 UL 1 data sheet.

Share the article on your favorite social:

Did you find the article interesting?

Are there any topics you'd like to see covered in this blog?

Your comments and requests are important to us: write them in the space below, it's available to you!