BIOPOLYMERS AND INDUSTRY: PACKAGING & COSMETICS

Published: 21/05/2021

The packaging sector is dominant in terms of annual consumption of plastics, if compared to any other industrial segment (i.e. Construction or Automotive)and in every country of the world. If we consider also that around 360 million tons of polymers are produced globally every year and that more than 40% of this enormous quantity of raw materials are absorbed by the packaging sector, we understand that we are talking about a consumption of over 140 million tons per annum.

A truly significant amount of polymers used for the production of primary and secondary protection systems (packaging), of food, medicines, cosmetics and many other products. A quantity that is expected to grow steadily, due to the growing hygienic requirements that have emerged in recent years. In particular, in Italy, the growth is also sustained by the food sector.

By analyzing the world statistics of productions, in addition to the leadership of the packaging sector another interesting aspect is emerging; the most widespread plastics processing technology in the world is Extrusion. It is dominant in any country in the world, covering 40%-45% of plastic production. The second is injection molding, which is used in 20%-25% of production (for further information on consumption and technologies in the countries of the world see www.euromap.org).

This segment/technology relationship becomes interesting when linked to the types and shapes of packaging on the market. It influences the research of the best polymers and of the best geometric/functional shapes, to obtain the best recovery/recycling system at the end of the product life. Especially when the target is to enhance the circular economy and to reduce the consumption of raw materials.

As we have already pointed out (see previous blogs), the packaging segment is also the segment that is currently paying a high toll, higher than others, due to the consequences of an inadequate education policy of public consumers. A big gap, which has led to a planetary catastrophe in terms of plastic soil and sea pollution.

Today it is certainly the sector that, more than others, is going through a moment of great innovative ferment that involves the entire value chain. Certainly the basis is the fact that the European “Green Deal” has heavily shifted the focus on the recovery of packaging. In fact, until now there has never been a clear input for the recovery, or reuse, of these products and the materials that compose them. Therefore, landfill or incineration were the most used practices for their disposal. This new virtuous approach will be increasingly crucial to achieving the goal of reducing consumption of virgin raw materials. Some large multinationals in the food sector have already taken a precise stand, declaring their firm intention to reduce the consumption of plastic packaging within the next 10 years.

An important commitment that involves and conditions all the players in the segment. Those who produce the raw materials will have to make them less and less impacting and more and more performing. Those who design the packaging will have to imagine them as reusable and, if made with more than one raw material, make sure that the different materials are easily separable. The packaging will have to be less and less complex in structure, while it will become functionally more and more performing (eg use of “explicit” labels), in order to allow a correct management of their end of life.

It is certain that in the coming years more and more precise laws and directives will be introduced, to guide the transition and support the most deserving projects that lead to more efficient, reusable and, or, completely recyclable systems.

From the point of view of the raw materials used, although the packaging segment is an extremely varied segment in terms of shapes and applications, it uses only five families of materials: Paper, Glass, Aluminum, Plastic. Certainly each of these macro families has multiple by-products. In the plastics, which we deal with, fossil materials are still prevalent at the moment. Here we can find: Polyethylene (PE) in all its forms (HDPE, MDPE, LDPE, LLDPE), Polypropylene (PP) homopolymer, copolymer, and random, Polyethylene terephthalate (PET) and Polystyrene (PS).

The importance of the segment for the world economy, as indicated, is strategic. Plastics remain essential to sustain growth and vitality. For this reason, the petrochemical industry is strongly focused on the research and development of new alternative solutions that are more respectful of the environment. Alternative raw materials to traditional products made through the re-conversion of obsolete plants, or to the adaptations of existing ones.

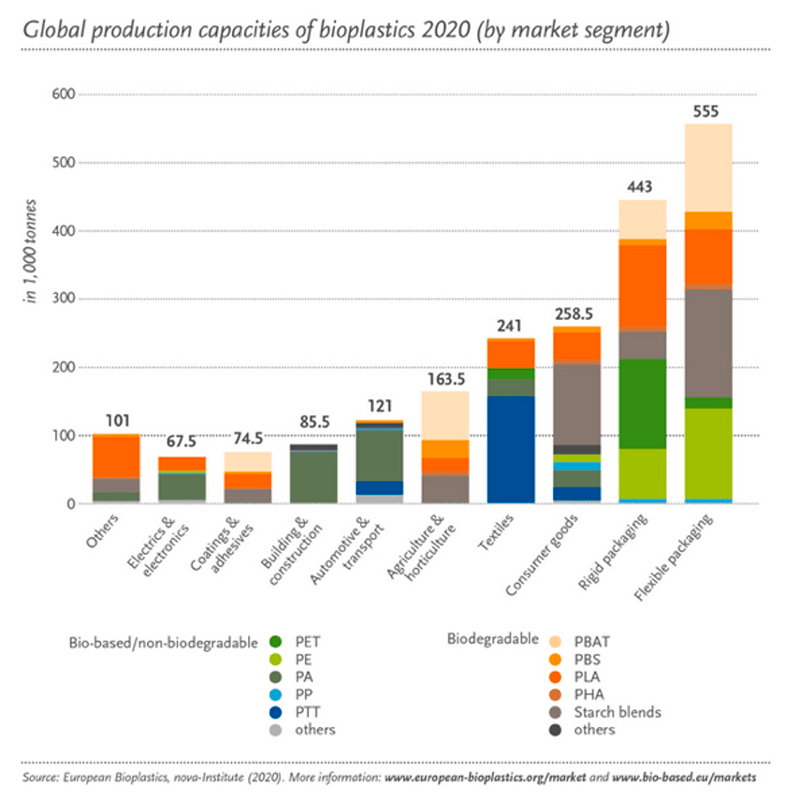

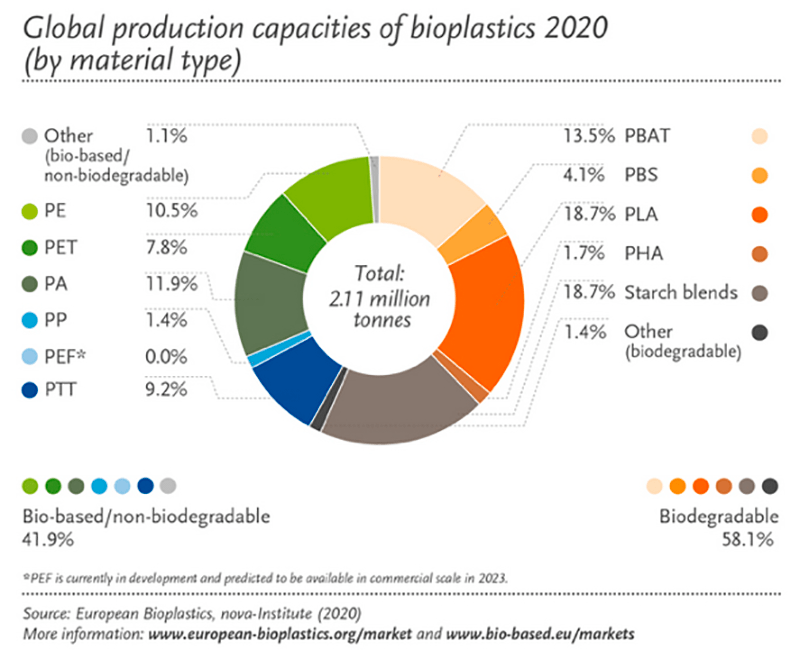

In the previous in-depth analyses we have seen how the rigid and flexible packaging segment is the driving sector, also for the new generations of Bioplastics. Although with considerably lower numbers than fossil materials (for now), the trend in consumption is already similar to that of traditional fossil products. In fact, even here, more than 40% of these new raw materials are absorbed by the rigid and flexible packaging sector.

The race to replace fossil polymers with sustainable materials is in full swing. Research and development is making great strides, as always happens when it is focused, in the creation of monomers similar to fossil ones but deriving from renewable biological sources.

Among the biobased polymers made entirely from renewable sources, we can mention bioPE (from sugars) and bioPA (from castor oil). Solutions that have shown the way for the production of materials that instead of having a CO2e debt (for some polymers is 5 times higher that their weight) boast a credit of two or three times their weight (e.g. bioPE = -3ton/ton).

Even in the worst conditions, the new partially biobased and, or, hybrid polymers offer CO2 values that are at least 50% lower than those of their fossil brothers, with the same technical performance. This allows producers of semi-finished products to use the same production plants without reducing their productivity.

The re-conversion of the polymerization plants from fossil to bio requires investments and these obviously reflect on the costs of these new materials. On the positive side, Europe is pushing for change, the demand for packaging polymers is growing as well as the prices of fossil raw materials. All these elements create the conditions to reassure investors on the return on investments, necessary to continue the green transition. Furthermore, the new biobased raw materials, even if not degradable or compostable can be easily reused at the end of their life, or reprocessed to obtain new artifacts, exactly as happens with the fossil versions. Certainly in order not to nullify the acquired advantage, it will be useful to avoid that they end up in an incinerator or in a landfill.

However, despite the particular focus on recycling and reuse of packaging, supported by non-degradable biobased materials, the completely biodegradable and compostable raw materials are growing in quantity and range, and find their natural outlet in packaging for fresh food products, fruit and vegetables. In the table shown here we see the most popular compostable biobased materials for packaging and these are: PLA, Starch Polymers (100% organic), PBAT and PBS (50% organic). A rather interesting, although still a marginal contender, is the PHA (or, the PHA family) we should keep an eye on. As well as the PEF (Polyethylene Furanoate) alternative to bioPET.

Thanks to compounding techniques, there are also excellent biodegradable solutions available on the market today, made of two or more materials. Custom-made products suitable for injection molding or injection-blow molding conversion technologies (for further information on these technologies see the blog articles dealing with injection molding and injection blow molding.

Among the sectors that mainly use injection molding and injection-blow molding technologies, for their packaging, there is certainly the cosmetic; a sector with a higher degree of complexity than many others. Generally, in this segment there are two packages, the primary packaging (e.g. jar, bottle, ampule, tube) that contains the active product (cream, gel, liquid, etc …) and the secondary packaging that protects the finished product (i.e. a box, a transparent film); two worlds with very different needs in terms of end of life handling.

The finished products of this segment, in turn, can fall into the categories of non-durable goods or semi-durable ones.

For primary casings, in addition to other technical aspects, from the material selection point of view, it is necessary to consider the fact that the finished product may not be used quickly and all at once. In fact, it could remain on the store shelf, or in the locker at home, for a certain time.

It is therefore quite intuitive that primary packaging is the one with the greatest complexity that should be analyzed thoroughly when we decide to adopt a biodegradable, compostable material. In this case, the chemical constituents of the active product must be analyzed very well. Prolonged contact with the organic raw material, for an unpredictable time, except for that expiry date indicated by the producer, could alter the chemistry of the material precluding composting at the end of its life (EN13432-2002 standard).

Conversely, the active content, product, present in the packaging could extract and adsorb some less stable elements of the polymer, undergoing some alteration (i.e. color, odor).

In this segment, the choice of material for primary packaging is therefore a delicate step. It is therefore not surprising if in this first phase of the transition the industry is oriented towards non-biodegradable hybrid or fully Biobased products, or on traditional fossil polymers with a high content of recycled material.

Both solutions can replace traditional materials while reducing the carbon footprint of the finished product and the risks deriving form other variables such as: chemical resistance, barrier effect, transfer/absorption of substances. We are sure that over time, all the necessary chemical-physical property information about biodegradable materials will be made available by the producers, as has happened in the past for fossil polymers.

For the moment, cosmetic manufacturers wishing to transform their primary packaging from fossil to degradable, or compostable, cannot fail to conduct the necessary chemical compatibility tests in contact with the chosen polymers.

So? When do we choose biodegradable and compostable products?

In our opinion, to answer this question we need to start from the end. We must ask ourselves what the final destination of the packaging will be. If the packaging can easily fall within the recovery cycle of traditional plastics, making it with bio-based, hybrid, or partially recycled materials will be the best solution. It will allow for a significant reduction in the CO2 content of the finished product. Provided that product regulations (i.e. food contact) are respected, that there are no specific laws on the horizon that lead to different choices, as is happening to “disposable” products (see SUP regulations).

If, on the other hand, the finished product has characteristics of rapidity of use (short life cycle), is widely consumed, is mono-material or has been designed to facilitate the rapid separation of any non-compostable elements (design for disassembling), it is not chemically contaminated; then the best choice is certainly the biodegradable and compostable products. This choice reduces the impact of CO2 and offers a quick, practical and virtuous way for disposal at the end of its life.

Whatever solution is adopted, we believe that it will always be good to carry out an LCA analysis and communicate to customers the goal achieved thanks to it. It will be essential to communicate better the best method of disposal to be adopted with your packaging.

As we know, the cosmetics sector needs to recover credibility with public opinion. The information that has circulated on the health of the seas has brought to light the problem of micro-pearls to the fore. Polymeric micro-particles (usually PE) with dimensions from 1.0 mm to 0.01 mm, inserted in personal care products such as: shampoos, exfoliating creams, sun lotions, moisturizers and make-up products.

These non-biodegradable particles have one more problem, they are ready for use, that means, ready to cause damage. When we talk about micro-plastics, we generally refer to fragments with dimensions of about 5mm. Any plastic object (i.e. a bottle) must remain in water for several years to reduce to this size. The cosmetic micro-spheres, on the other hand, arrive at the sea already with a useful dimension to directly enter the food cycle of marine fauna.

In October 2015, the COSMETIC EUROPE2) association recommended to all its members to stop, by 2020, the use of solid synthetic particles (micro spheres in fact), which are not biodegradable in the aquatic environment. A process of conversion to organic that is still in progress and that we hope will be completed quickly and definitively.

Note: in the recent past a new and greater danger has emerged for the marine environment and for us. Due to Covid19, synthetic protective masks entered the world market. Most of these products are composed of polypropylene micro-fibers, held together by electrostatic forces (there is no warp and weft).

These forces in contact with water will rapidly reduce, releasing the fibrils that will rapidly contaminate the marine ecosystem.

As plastics operators we can only be thrilled. Again, as in the past, new potentially polluting plastic products have entered in public availability without a single word about their composition and their enormous environmental risk if not disposed of properly.

Again a problem of non adequate public education.

In other words, we suddenly went back to the past, to the years of “disposables” that led us to the islands of plastic in the ocean and to the “demonization” of plastics. The good news is that this time we will not see the plastic islands (what a stroke of luck!) because we will find these micro fibers quickly and directly in our food or in our drinking water.v

Share the article on your favorite social:

Did you find the article interesting?

Are there any topics you'd like to see covered in this blog?

Your comments and requests are important to us: write them in the space below, it's available to you!